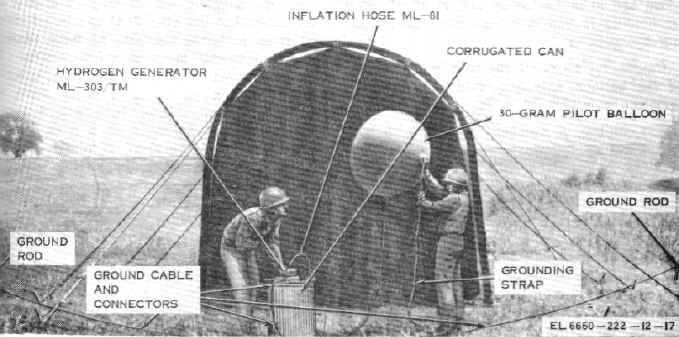

Pilot Balloon Inflation - Example of Protective Grounds and Safety Precautions

This page is not intended as a tutorial on safety working with hydrogen. Its intention is only to give an example of the complexities of working safely with hydrogen. Please refer to a comprehensive safety manual before working with hydrogen gas, or hydrogen generators!

Protective Grounds and Safety Precautions:

The generation and use of hydrogen is dangerous. Mixtures of hydrogen and air can be highly explosive. Never smoke near a place where hydrogen is generated or being used. Remove all possible sources of flame and sparks. Hydrogen should only be generated and used in a well ventilated out door area. Precautions must be taken to remove all possibilities of fire or explosion. The following are an example of some of these precautions.

Dangerous heat and chemical reaction may result from incorrect operation of hydrogen generators. Removing a hydrogen generator from a water tank while in operation will produce excessive heat and may cause a dangerous chemical reaction. Never remove a generator from the water while in operation until the generation of hydrogen gas has stopped.

a. To provide a path for for any static electrical charge generated in the equipment, ground all inflation equipment as follows:

1. Drive two copper grounding rods, spaced 5 feet apart into the earth to a depth of at least 3 feet.

2. Measure the resistance between the two rods with an ohmmeter. The resistance should be less than 1,000 ohms. If the resistance is more than 1,000 ohms, add as many rods as needed, at 4 foot intervals until the resistance measures less than 1,000 ohms.

3. Connect the grounding stakes to the balloon launcher using a grounding cable, or to the water can when a hydrogen generator is used.

b. Prepare wire strap grounding connections to interconnect all metal parts of the inflation equipment as follows:

1. Clean the metal surfaces of all metal parts with sandpaper to expose the bare metal.

2. Make enough ground straps to interconnect all parts. Use wire and alligator clips or ground clamps.

3. Interconnect all metal parts with the ground straps.

4. Connect a ground lead from the equipment to the grounding rods.

c. Personnel grounds are required when woolen or fur, or synthetic clothing is worn to provide a path to ground for static electricity. Wear a wristband of metal connected to a good ground. For convenience, use a plug at the end of the wire from the wristband , and a jack permanently connect to ground.