Long wavelength flow:

Long wavelength flow:

A mechanism for controlling this pattern may be to impose a temperature

gradient normal to the substrate. Large temperature gradients should

exist during not-so-well controlled quenches from high to low temperature.

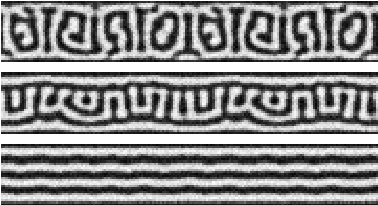

Two effects have been studied through simulation: the effect on the

film order of maintaining a static surface-normal temperature gradient,

and the possibility that this gradient could give rise to hydrodynamic

flow in the layers. The following pictures were grabbed from a simulation

on symmetric diblocks subjected to the steady, convective (divergenceless)

flow shown at the right. At each time, the upper panel shows the

situation when the peak convective velocity is 0.5 in dimensionless units,

the middle panel shows the situation with a convective flow that is five

times slower, and the lowest panel shows the quiescent layer, quietly arranging

itself in uniform wetting layers. Each panel was started with the

same random initial configuration, and was subjected to the same sequence

of order-parameter conserving noise.

Short wavelength flow: Long wavelength flow:

Long wavelength flow:

You can download this animation in avi format. Here is another animation file showing what happens when the wavelength of the flow pattern is doubled, with everything else the same.

The boundary conditions are chosen so that the dark-"stained" portion of the diblock is attracted to both the upper and lower rigid surfaces, and laterally periodic boundary conditions have been enforced. The diblocks are not quite strongly segregated. The lattice used in the calculation is 30X90 units, but two repeat sequences have been plotted here.

At this point, the lateral order in the films is entirely a result of

the externally applied flow. The upper flow is strong enough so that

the order which arises does not extend past a single convective cell, whereas

the middle panels with the "slow" stirring show ordering that extends throughout

the system. Also, the middle panel order gets stuck, and releases

its stresses at discrete times during the simulation. When the flow

is much weaker than the thermodynamic forces driving the pattern formation,

this sort of stick-slip motion occurs. The missing element at this

point, and which I am currently working, is coupling the flow to the striped

patterns, and determining if these circulating flows can be induced and

controlled by adjusting the temperature gradient across the film.

time= 0005

time= 0250

time= 0500

time= 0750

time = 1000